Business Process Management (BPM)

People & Operations in Harmony

Looking for thoughtful solutions to optimize performance efficiencies, integrate processes, systems, and technologies? Our modus operandi to Business Process Management (BPM) aims to create unified, streamlined, and scalable processes, where people and operations can live in harmony.

Profit From Process

BPM Services

- Business case opportunity identification & evaluation

- Process performance & impact assessment

- Financial controls assessment

- Margin optimization assessment

- Resource optimization

- Improve process improvement governance & control framework

- Workflow analysis & field studies

- Process documentation, mapping and modeling

- Reengineer approach to operations, sales, quality, product development, solution architecture

- Implementation strategy

- Post-implementation support

- Tools used: ProVision, MEGA, Casewise, Visio, and others

- Application of Lean Six Sigma, Total Quality Management (TQM), Kanban, Systematic Inventive Thinking (SIT)®, and Theory of Inventive Problem Solving (TRIZ) methodologies

- Set up BPM Center of Excellence (deploy, operate, enhance)

- Monitor process effectiveness and operations performance

- Benchmark metrics and KPIs to exceed industry comparatives

- Process improvement benefits realization

- Refinement and implementation planning

- Waste elimination

- Balance scorecards

- Train process managers

- Quality control

- Cost reduction

Automate, Simplify, Humanize

Methodology

Doing more with less isn’t always easy. We’re here to help. We aim to align your business processes with your strategic organizational goals, so that every activity yields optimal performance. We partner with you to objectively assess your current processes, to identify and prioritize gaps and opportunities to improve efficiencies. From our findings, we work with you to design a sustainable target-state roadmap, implement solutions, and monitor, analyze, and report improvements over time.

The Concept Key BPM method is how we engage with your organization to improve operations and processes. Our unique approach puts people before process, productivity before politics, purpose before jargon, and sustained growth before accelerated growth.

- Evaluate current operations processes, tools, and techniques

- Identify high and low value stream processes

- Identify bottlenecks and root cause of process inefficiencies

- Analyze process requirements and organizational capabilities

- Business case and cost benefit analysis

- Identify and rank strategic business metrics and KPIs

- Define business objectives, roadmap, migration strategy and target operating model

- Define process improvement metrics and process management strategies

- Gap analysis (current state vs. target state)

- Process modeling and reengineering

- Plan realization of benefits throughout transformation lifecycle

- Integrate improved tools and process-methodologies into operations

- Apply and implement BPM industry best practices

- Enable processes for smooth deployment transitions

- Hold knowledge transfer sessions, training stakeholders on new processes

- Track, analyze and report efficiency improvement metrics and benefits realization

- Reassess strategic alignment with stakeholders

- Drive continuous improvement (Kaizen) initiatives

“Do things right the first time, every time.”

Evolving from the manufacturing quality assurance methods developed in World War 1, Total Quality Management (TQM) is a continuous improvement methodology that measures long-term success through the lens of customer satisfaction. In TQM, all members of an organizations participate in improving products, services, and processes. Slightly different than Six Sigma, TQM focusses on ensuring process standards and guidelines reduce errors, whereas Six Sigma focusses on reducing defects.

We use the following 8 principles of TQM to help your organization prosper:

1. Customer-Driven

TQM efforts (training employees, streamlining processes, upgrading technologies) are geared towards helping improve the customer experience. Consumer behavior is the ultimate judge of the effectiveness of TQM efforts.

2. Total Organizational Commitment

All members of the organization should be empowered to pro-actively identify and address quality related problems.

3. Process Centered Thinking

TQM emphasizes the use of methodologies and tools, required to carry out processes, to be granularly defined, and for performance measurements to be continuously monitored

4. Integrated System

An integrated system is one where there is harmony in the vision, mission, guiding principles, quality policies, critical processes, objectives, milestones, and culture in an organization. Well designed integrated systems that are adopted throughout the organization aim to continually improve upon the expectations set by customers, employees, and other stakeholders.

5. Strategic and Systematic Approach

A quality plan should be a core component of a strategic management plan, so that an organization’s vision, mission, and goals are met.

6. Continuous Improvement

Adopting an always-improving mindset, drives an organization to find new ways to be more effective in meeting stakeholder expectations and in turn be more competitive in the marketplace.

7. Fact-Based Decision Making

For improving the accuracy of decision-making and forecasting, TQM advises an organization to gather and analyze performance data on a continuous basis to measure quality metrics.

8. Effective Communication

Organizations should develop comprehensive communication plans that increase employee involvement in TQM efforts as well as boost morale.

Check Sheet – a check list form that facilitates inspection of quality for recurring data

Pareto Chart – a chart that helps identify which problems fall into which categories, under the belief that 80 percent of problems are related to 20 percent of causes

Ishikawa Fishbone Diagram – a diagram to visualize all the known causes and effects of a problem, in an effort to find the root cause

Control Chart – a chart which shows how results and processes change over time

Histogram Bar Chart – a bar chart that shows the frequency of a problem’s cause, and how and where results cluster

Scatter Diagram – a diagram that plots data on x and y axes to see how both variables affect change

Flow Chart – a chart that represents how different steps join in a process or workflow

Lean Six Sigma is a synergistic methodology that aims to improve performance by reducing waste and process variation. Lean methodology works to reveal areas of process waste/variation and Six Sigma aims to reduce that waste/variation. This, in turn, drives continuous virtuous cycles of iterative improvement towards specific goals. We help adapt principles of Lean Six Sigma to your organization, so you can minimize costs, maximize profits, and ultimately improve the customer experience.

- Lean focusses on speedy removal of non-value waste steps from process

- Six Sigma focusses on improving quality processes by reducing process variation

- Value defect prevention over defect detection

- Aim to drive customer satisfaction and bottom-line by reducing waste/variation in process

- Promote process standardization as a vehicle for creating a competitive advantage

- Find and define value streams by meticulously observing how work is done

- Defects

- Inventory

- Transportation

- Over-Production

- Waiting

- Non-Utilized Talent

- Motion

- Extra-Processing

The 5 DMAIC phases refer to a continuous improvement cycle used for optimizing and standardizing business processes.

1. Define – Define and clearly articulate the process, the problem, and intended process outputs

2. Measure – Quantify the problem; Collect data, evaluate current performance, and set performance metric baseline(s)

3. Analyze – Identify, investigate and priories root causes of the problem

4. Improve – Implement process improvements that solve the problem; Test and verify solutions

5. Control – Monitor and sustain the solution/results; Update control and quality management plans and decide on further improvements

Developed by engineers at Toyota, Kanban (meaning signboard in Japanese) is an inventory-control system aimed to improve supply chain efficiency and management. Kanban techniques help organizations respond quickly to customer demand, reduce unnecessary inventory, improve workflows, prevent overproduction, and ultimately save on production costs.

1. Visualize the Workflow

Break down work into smaller parts and use a (signboard) visual to display work hierarchy. This visual helps bring to light any bottlenecks or blockers that hinder efficiency, resulting in improved transparency throughout the entire workflow

2. Limit Work in Progress

To avoid overcapacity problems, Kanban suggests to assign limits to how many tasks can run in each workflow phase

3. Measure Lead Time (Cycle Time)

Track the time it takes to complete one deliverable; aim to improve the process so that the lead or cycle time is consistent and as short as possible.

Developed in Japan and part of Kazien philosophy, the 5S technique enables continuous improvements initiatives that lead to less waste, improved quality, and faster flow (lead) times.

Sort (Seiri) – Sort through contents of the workplace and remove unnecessary items

- Defining what is needed and not needed to complete work

- Developing criteria for removal of not-needed items

- Red-tagging items that will be changed or removed

Systematize (Seiton) – Arranging needed items in place and ensure they can be easily accessed

- Make sure all unnecessary items are removed

- Align needed-contents with workflows, placing them in a logical and efficient order

- Arrange needed contents by order of frequency used

Sweep (Seiso) – Clean the workplace frequently and using this cleaning as a technique to inspecting defects and inefficiencies

- Clean your workplace on daily basis (consistently and completely)

- Use cleaning as inspection

- Prevent tools and equipment from deteriorating

Standardize (Seiketsu) – Develop governance frameworks, guidelines, and controls for converting the first three S’s (Sort, Systematize, Sweep) into business as usual

- Standardize and implement best practices across processes

- Visualize all team activity and procedures

- Coordinate frequent audits and evaluation by a cross-functional team(s)

Self-Discipline (Shitsuke) – Hold 5S discipline training for the organization to maintain 5S standards

- For greatest success, the 5S’s should be treated as an integrated concept of actions, conditions, and culture

- Managers and Operators hold discipline trainings to ensure that everyone follows the 5S standards

- Employees proactively take part to maintain the 5S’s

The Plan-Do-Check-Act (PDCA) method is a framework, popularized by William E. Deming, who some believe to be the “father” of modern quality control. Designed for continuously improving the quality of processes, products, and services, organizations use the PDCA model for problem solving, continuous improvement and for managing transformation. We partner with you to take your organization through these cycles until an optimal solution is reached.

- Identify and describe problem with process

- Develop strategic & tactical plan and goals

- Define target metrics

- Forecast results and performance expectations

- Execute the plan

- Take small steps to test potential solutions in controlled circumstances

- Record actual results

- Troubleshoot unexpected issues that arise during operations

- Compare results (variance analysis: forecast vs. actual results)

- Gather feedback from process participants and stakeholders

- Identify root cause(s)

- Document all learnings from cycle (audit)

- Take action to maintain or improve the process

- Develop preventive or corrective actions

- Improve strategic and tactical plans

- Incorporate learnings to improve the next cycle

The TRIZ method emphasizes the use of logic and data to find patterns of problems and solutions, advising against the use of intuition and emotion. Coined by USSR engineer and inventor, Genrich Altshuller (and colleagues), TRIZ was created to identify and codify universal principles to make the process of creativity more effective and predictable. More than 3 million patents have been analyzed and codified using TRIZ, finding patterns that predict ground-breaking solutions to problems. The application of TRIZ for organizations is in discovering and analyzing repeating patterns of problems and solutions, and then aligning those patterns with the evolution of technology. We help your organization harness its diverse minds to systematically think and adapt universal principles to solve problems.

Over the course of 60 years of research, the primary findings of TRIZ have been:

1. Problems and solutions are repeated across industries and sciences. The classification of the contradictions in each problem predicts the creative solutions to that problem.

2. Patterns of technical evolution are repeated across industries and sciences.

3. Creative innovations use scientific effects outside the field where they were developed.

TRIZ is an empirically-based algorithm, supplementing the emotional-based innovation methods such as:

Brainstorming – Generating ideas to solve a problem by holding group discussions

Synectics © – Joining together different and apparently irrelevant elements

Lateral Thinking – Understanding the “movement value” of statements and ideas

Neurolinguistic Programming – Examining behavioral patterns of experience through connections between neurological processes and language

Mind Mapping – Organizing random ideas into visual concepts, flows, or hierarchies

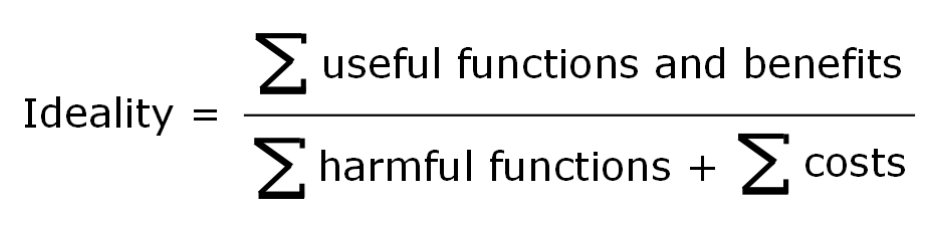

TRIZ uses the Ideality formula for understanding which variables contribute to the Ideal Final Result (IFR), the intended outcome of problem solving.

TRIZ aims to improve the Ideality metric by increasing the numerator value (useful functions and benefits) and decreasing the denominator value (harmful functions and costs).

What is the single major driver causing your organization to focus on business process change?

– The State of the BPM Market by Business Process Trends ©, 2015

100 surveyed business managers, BPM consultants, BPM practitioners, and business analysts said THE biggest driver is the:

The Art of Process Management

Balance

Does This Sound Like Your Company?

- Missing deadlines?

- Have out-of-date tools and processes that hinder project progress?

- Managing projects consistently behind schedule?

- Experiencing inefficient transitions between project phases?

- Having difficulty aligning processes to strategic goals?

- Want to improve process, quality and cost efficiencies?

Are You Looking For?

- A fresh perspective and evaluation of your business processes?

- Ways to integrate cross-functional processes and systems?

- More control over costs and operations?

- Best practices to foster a continuous improvement culture?

- A structured and measurable framework for executing process improvement initiatives?